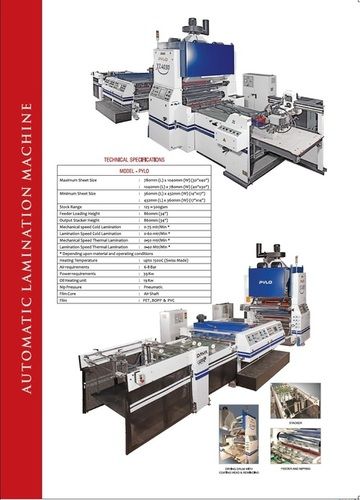

Automatic Film Lamination Machine

Automatic Film Lamination Machine Specification

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power Source

- Electric

- Warranty

- 1 Year

About Automatic Film Lamination Machine

Automatic Film Lamination Machine

Water Based Adhesive, Single Side Sheet to Reel Cold Lamination for BOPP Films-Matt, Gloss or Metallized.

Features

- Water Based, Single Side Sheet to Reel Cold Lamination.

- Films-Matt, Gloss or Metallized BOPP.

- Integrated feeder which can take stock from 120-450gsm.

- Sheets are fed on a vacuum bed with wide belts for precise underlap accuracy.

- Two laminating rollers-one hard chrome steel roller and second rubber roller are pneumatically controlled at the nip.

- Adhesive is pneumatically controlled and precisely dispensed by pneumatic pump, which ensures neat operation.

- The roll of film is mounted on quick-change airshaft with film tension controlled by a pneumatic brake.

- Film roll has a trim slitter and perforating mechanism.

- Laminated sheets are perfectly rewinded with separate drive on a specially devised roller, resulting in no wrinkles, ability to rewind large diameter rolls as per feeding stack and easily transferable to sheet separator.

- Entire process of feeding, laminating and rewinding as per increasing speed levels are synchronized and ensures non-stop laminating.

- Modular design machine, which can be run in conjunction with Sheet Separator machine essential for separating laminated sheets.

- The rewinded laminated sheets on roller are directly fed on separator.

- The in-feed nip rollers are pneumatically adjustable.

- The separated sheets are properly collected on a stacker.

Technical Details

- Maximum Sheet Size: 1040mm L x 780mm W (40"x30")

- 780mm L x 1040mm W (30"x40")

- Minimum Sheet Size: 432mm L x 360mm W (17"x14")

- 360mm L x 432mm W (14" x 17")

- Stock Range: 120 gsm to 450 gsm

- Speed: 0-70 Meters Per minute.

- Power Requirements: 9Kw

Sheet Separator Unit

- Power Requirements: 1.5 Kw

Option

Model JAZZ-CT for water based adhesive and thermal lamination.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FULLY AUTOMATIC LAMINATION MACHINES Category

MODEL PYLO AND JAZZ

Drive Type : Electric

Power Source : Electric

Automatic Grade : Automatic

Control System : PLC Control

Computerized : Yes

Double Side Digital Thermal Laminator

Minimum Order Quantity : 1 , , Piece

Drive Type : Electric

Power Source : Electric

Automatic Grade : Automatic

Control System : Frequency Speed Control

Computerized : No

Automatic Film Lamination Machine

Minimum Order Quantity : 1 , , Piece

Drive Type : Electric

Power Source : Diesel

Automatic Grade : Automatic

Control System : PLC Control

Computerized : No

Pacer Fully Automatic Film Lamination Machine

Minimum Order Quantity : 1 , , Piece

Drive Type : Electric

Power Source : Electric

Automatic Grade : Automatic

Control System : PLC Control

|

SHETH PRINTOGRAPH PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry