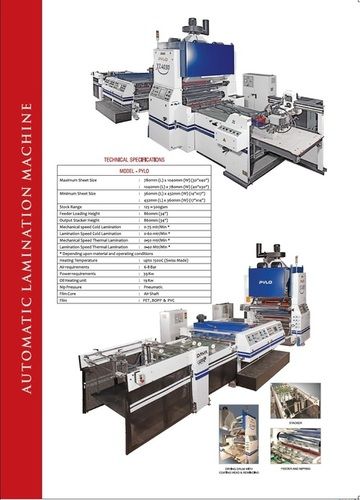

Automatic Film Lamination Machine

Automatic Film Lamination Machine Specification

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power Source

- Electric

- Feature

- Simple Control, High Performance, High Efficiency

- Warranty

- 1 Year

About Automatic Film Lamination Machine

Since our inception in the year 1963, we are engaged in manufacturing and exporting an excellent range of Automatic Film Lamination Machine. This machine is suitable to be used in the packaging industry for laminating the packaging materials with high accuracy. Offered machine is precisely manufactured at our sound production unit by making use of premium quality materials in adherence with the industry preset standards. This range of Automatic Film Lamination Machine is available with us in different sizes, models and specifications at cost-effective prices.

Features:

- Easy to operate

- Longer service life

- High speed performance

Further Details:

Automatic Film Lamination Machine

Water Based Adhesive, Single Side Sheet to Reel Cold Lamination for BOPP Films-Matt, Gloss or Metallized.

Features

- Water Based, Single Side Sheet to Reel Cold Lamination.

- Films-Matt, Gloss or Metallized BOPP.

- Integrated feeder which can take stock from 120-450gsm.

- Sheets are fed on a vacuum bed with wide belts for precise underlap accuracy.

- Two laminating rollers-one hard chrome steel roller and second rubber roller are pneumatically controlled at the nip.

- Adhesive is pneumatically controlled and precisely dispensed by pneumatic pump, which ensures neat operation.

- The roll of film is mounted on quick-change airshaft with film tension controlled by a pneumatic brake.

- Film roll has a trim slitter and perforating mechanism.

- Laminated sheets are perfectly rewinded with separate drive on a specially devised roller, resulting in no wrinkles, ability to rewind large diameter rolls as per feeding stack and easily transferable to sheet separator.

- Entire process of feeding, laminating and rewinding as per increasing speed levels are synchronized and ensures non-stop laminating.

- Modular design machine, which can be run in conjunction with Sheet Separator machine essential for separating laminated sheets.

- The rewinded laminated sheets on roller are directly fed on separator.

- The in-feed nip rollers are pneumatically adjustable.

- The separated sheets are properly collected on a stacker.

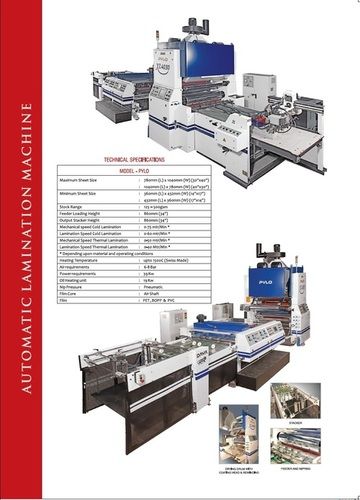

Technical Details

- Maximum Sheet Size: 1040mm L x 780mm W (40"x30")

- 780mm L x 1040mm W (30"x40")

- Minimum Sheet Size: 432mm L x 360mm W (17"x14")

- 360mm L x 432mm W (14" x 17")

- Stock Range: 120 gsm to 450 gsm

- Speed: 0-70 Meters Per minute.

- Power Requirements: 9Kw

Sheet Separator Unit

- Power Requirements: 1.5 Kw

Option

Model JAZZ-CT for water based adhesive and thermal lamination.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FULLY AUTOMATIC LAMINATION MACHINES Category

MODEL PYLO AND JAZZ

Automatic Grade : Automatic

Power Source : Electric

Control System : PLC Control

Drive Type : Electric

Sprint Automatic Thermal Lamination Machine

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Power Source : Diesel

Control System : PLC Control

Drive Type : Electric

Warranty : 1 Year

Sheet Board Pasting Laminator

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Power Source : Electric

Control System : Frequency Speed Control

Drive Type : Electric

Warranty : 1 Year

Pacer Fully Automatic Film Lamination Machine

Minimum Order Quantity : 1 , , Piece

Automatic Grade : Automatic

Power Source : Electric

Control System : PLC Control

Drive Type : Electric

Warranty : 1 Year

|

SHETH PRINTOGRAPH PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry